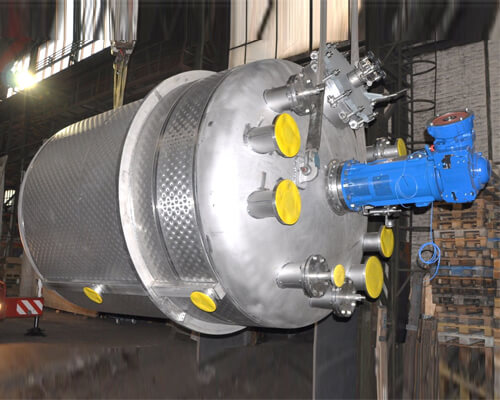

Agitator Tank Manufacturers in Chennai Call 9940306697

Agitator Tank Manufacturers in Chennai –Tech Weld Engineering Pvt. Ltd. is a best Agitator Tank Mixers ideal for being used for the purposes of Mixing.

Tech Weld Engineering Pvt. Ltd. – Being one of the most zealous Agitator Tank Manufacturers in Chennai, we take the responsibility of meeting customer requirements very seriously. Each design that passes from our site will give our customers never before experience. We have the best solutions for Agitator Tank. We don’t believe in sell and forget, but in maintaining a business relationship for a long time and thus, won’t mind walking extra miles. We put quality assurance as one of our highest priorities. Satisfying the client by delivering world-class machinery can only be done when these machines go through multiple quality tests.

Quality Of An Agitator Tank in Chennai

The quality of an agitator tank is determined by the choice of materials, fabrication techniques, design, agitator quality, sealing mechanisms, and adherence to industry standards. High-quality agitator tanks are more reliable, longer-lasting, and better suited to their intended applications.

- Material Selection

- Welding and Fabrication

- Design and Engineering

- Agitator Quality

- Sealing Mechanisms

- Surface Finish

- Testing and Inspection

- Compliance with Standards

- Customization

- Maintenance and Serviceability

Manufacturer, Trader Service Provider Supplier

Our ultra modern Agitator tank enables us in meeting bulk and urgent demand of the customers on time. For easy identification the store in warehouse is segmented into various sections. Further, with the support and guidance of our manager. we have carved a niche for ourselves in the market in short period of time.

Within all these years, since from the year of establishment, different processing industries have grown to believe in our company, as a reliable and durable brand. This is owing to combined efforts of our skilled and efficient team that has boosted their confidence and provides the best solution to clients. Our goal is to provide quality products to every customer across Chennai, representing the best mix of performance and value under one roof.

Agitator Tanks Specification

| Tank Orientation | Horizontal, Vertical |

| Steel Grade | SS304L, SS316L, SS304, SS316 |

| Storage Capacity | 500-1000 L, 250-500 L, 5000-10000 L, 1000-5000 L, 0-250 L |

| Storage Material | Gas, Water, Chemicals |

Tech Weld Engineering Pvt. Ltd. – Our organization with the aid of its efficient manpower offers to our client’s best ranging SS Liquid Storage Tank. This SS Liquid Storage Tank has been designed keeping in mind exact client’s requirements. It boasts of sturdy construction, uniform surface area and has optimum tolerance capacity. Stainless steel of best quality has been used for manufacturing process. We are offering this SS Liquid Storage Tank at leading market price.

Features:

- Extensively used

- Reasonable price

- Reliable